LEVOTAN® / LUBRITAN™

Looking for higher performance?

Benefits delivered with multifunctional softening polymers

The Background

Tanners around the world are facing increasing challenges from their customers, for example, demands for higher performance such as fastness to light and heat resistance, but also lighter weight leather and more recently odour / emissions avoidance.

They are also facing increasing regulation issues, such as pressure to reduce water consumption, lower COD, cleaner effluent and at the same time trying to maximize cutting yield and at least maintaining the all- important essential aesthetic properties, such as the leather feel, tightness, fullness etc.

TFL high performance softening polymers are a proven way to achieve demanding targets, such as light and heat resistance, by substituting lower performing traditional retanning and/or fatliquoring agents and often simultaneously. They are also energy efficient, e.g. such polymers can even be applied in cold water.

The Benefit

TFL softening polymers combine at least two key functions, namely polymeric retanning and softening in one product where they can replace from a proportion up to the total fatliquor offer.

In general TFL softening polymers possess common properties

- high fastness - resistance to light and heat - and thermal stability

- free of AOX, formaldehyde, acetaldehyde and bisphenols

- good filling properties, tight grain together with a varying degree of softness

- by replacing traditional fatliquors, high flame resistance can be achieved

- lighter weight, low density even “fluffy” character possible

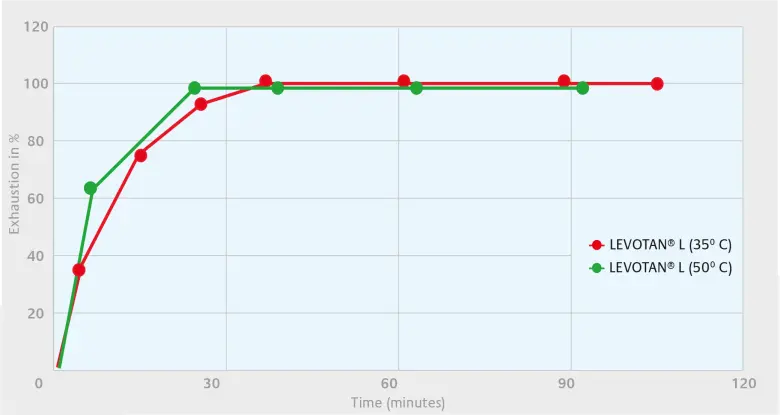

- high fibre affinity thus excellent exhaustion with low COD and improved washability

- low/no emissions – VOC / fogging and neutral odour

- low/no migration

- good dyeability and levelness

This range also includes special products with additional functionalities

- improved physical properties, such as tear and tensile strength

- protection against Chrome (VI) formation caused by the autoxidation of natural fats

- improved acetaldehyde / VOC / fogging values

- odour-avoiding properties

- bio-mimicry with improved biodegradability, compost ability and no significant effect on plant growth

Main Reaction - The TFL Blog Stories, incidents, tips and facts around the topics leather, chemistry, fashion, sustainability and ecology. Our editorial staff consisting of experienced tanners, scientists, market experts, fashion and communication specialists has sharped their pencils and will supply you with fresh and inspiring content on a regular basis.

Main Reaction - The TFL Blog Stories, incidents, tips and facts around the topics leather, chemistry, fashion, sustainability and ecology. Our editorial staff consisting of experienced tanners, scientists, market experts, fashion and communication specialists has sharped their pencils and will supply you with fresh and inspiring content on a regular basis.

LEVOTAN® / LUBRITAN™ - Looking for higher performance? Tanners around the world are facing increasing challenges from their customers, for example, demands for higher performance such as fastness to light and heat resistance, but also lighter weight leather and more recently odour / emissions avoidance.

LEVOTAN® / LUBRITAN™ - Looking for higher performance? Tanners around the world are facing increasing challenges from their customers, for example, demands for higher performance such as fastness to light and heat resistance, but also lighter weight leather and more recently odour / emissions avoidance.